Introducing GCBASIC

Hello, and welcome to GCBASIC help. This help file is intended to provide you insights and knowledge to use GCBASIC.

For information on installing GCBASIC and several other programs that may be helpful, please see Getting Started with GCBASIC

http://gcbasic.sourceforge.net/starting.html

If you are new to programming, you should try the GCBASIC demonstration programs these explains everything in a step-by-step manner, and assumes no prior knowledge.

If you have programmed in another language, then the demonstration files on GitHub ( or within your installation ) and this command reference may be the best place to start.

If there is anything else that you need help on, please visit the GCBASIC forum

http://sourceforge.net/forum/?group_id=169286

Using GCBASIC

Need to compile a program with GCBASIC, but don’t know where to begin? Try these simple instructions:

- Complete the installation using the default values - select all the programmers but not the portable mode.

- The installer will automatically start the IDE.

- When a GCBASIC source file is opened, check out the “GCB tools” menu ( IDE Tools / GCB tools ) - through this menu you can access the oneclick commands. Or try the right mouse button - this will access the same options.

- The IDE Tools… commands (function keys F5 - F8) starts a GCBASIC utility which calls the batchfiles for compiling sourcecode and programming

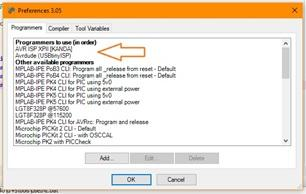

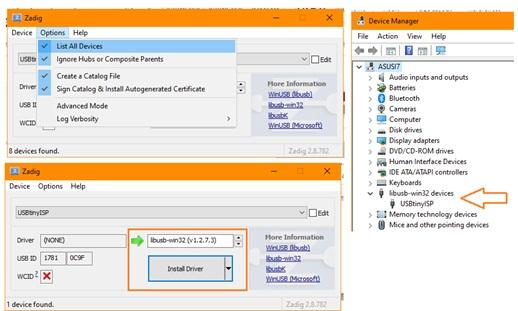

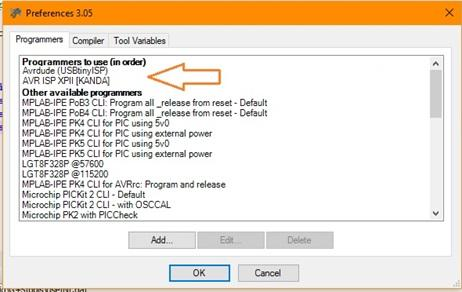

("flashing")(1) the target microcontroller. You have to select the appropriate programmer in “Edit Programmer Preferences” ( IDE Tools / GCB tools / Edit Programmer Preferences or by pressing Ctrl+Alt+E ). Find your programmer in the list and drag it to the top beneath the heading “Programmers to use (in order)”. GCBASIC will now attempt to flash the microcontroller with that programmer first when you click on "Make HEX and FLASH" ( F5 ) or "FLASH previous made hexfile" ( F8 ).

- In the unlikely event that your programmer is not listed you can add it by pressing “Add…” in “Edit Programmer Preferences”. You would have to know the working directory and command line options etc. for the programmer. See the help tips at the bottom by clicking on the fields.

- For project-specific flashing you can edit the current programmers in “Edit Programmer Preferences” to suit your needs by clicking on “Edit…”. Use the “Use If:” parameter to choose programmer preferences. See the help tips. The chip model is autodetected by the IDE for use in “Use IF:” or in command line options etc.

- Some programmers use a .hex file to "flash" the microcontroller. By selecting "Make HEX" ( F5 ), GCBASIC will compile the program and make a .hex file in the same directory as the GCBASIC file. This method can also be used to check for errors in the GCBASIC program before flashing.

- Included programmer software is:

— Avrdude for AVR,

— PICPgm for PIC,

— PicKit2 and PicKit3

— TinyBootLoader+

— Arduino

— Northern Software Programmer

— Microchip Xpress Board and many, many more.

(1) You need a suitable programmer to do this, and instructions should be

included with the programmer on how to download and connect the hardware to the microcontroller.

Programmer Preferences

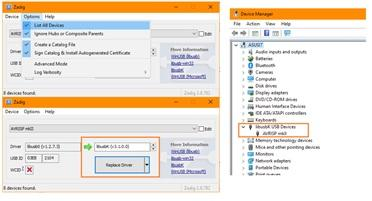

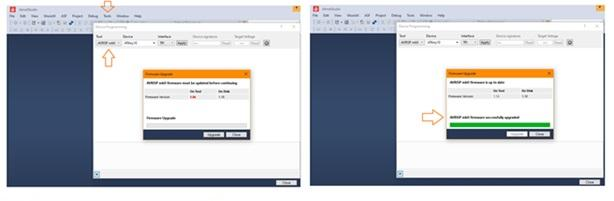

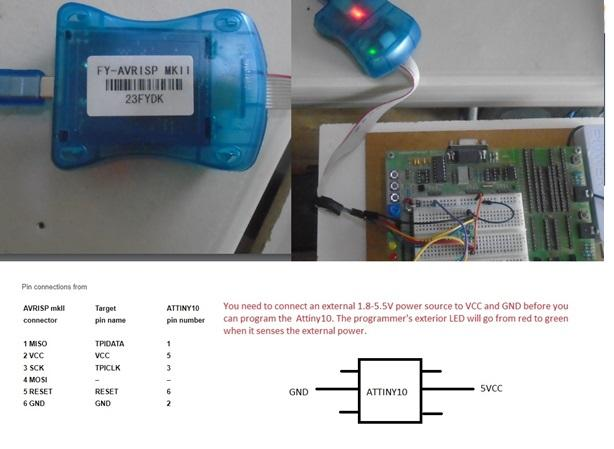

The “Programmer Preferences” is a software tool to control and set-up the different programmers. See below:

When using GC Code at the IDE

Select Terminal/Run Task or press function <F4> to see the menu

Or, when using GC Code at the IDE

Select the drop down menu to see the menu

When using SynWrite at the IDE

PIC users and Beginners: Start Here

Welcome to GCBASIC. This document is especially important for experienced PIC users moving from MPASM or C so please spend a few seconds here before you start. It could save you hours of frustration.

As a PIC user most of us are conditioned, regardless of the Assembler or Compiler, to reach for the devices data sheet first and try to work out how to setup the Oscillator, interrupt vectors and Configuration bits.

Do not DO IT. read this document first as it will give you some great insights. For the basic operation the only setup and configuration required for a GCBASIC program is the name of the target Device i.e. #Chip 16f1619. That is it, honestly, GCBASIC will do the rest and will determine the optimal Oscillator settings, interrupt vectors, Configuration bits etc

Next we would start deciding on and including the Device files and libraries that we intend to use. STOP. Let GCBASIC decide. GCBASIC is creating Portable Code, it doesn’t care if you use a PIC12, PIC18 or an ATmega328. You write in BASIC and at compile time GCBASIC will decide which core libraries to include based on the instructions you have used and the target device you specified in the #chip statement.

Finally we would decide on the pins to use, their port names, which register bits are needed to make them inputs or outputs and override any Analog function if a digital function is desired.

Again, I say let GCBASIC DO IT……… Dir PortC.0 In - Will set Pin RC0 to a Digital Input. There is no need to manually set the TRIS register or see if there is an associated ADCON bit to set or clear.

Putting it all together: An example GCBASIC program.

#Chip 16f1619

#Define LED PortC.0

Dir LED Out

Do

LED = !LED

Wait 500 ms

Loop

That is it. If you have an LED attached to PortC.0 (LED DS1 on the Low Pin Count Board that shipped with the PICKit 2 or PICKit 3 programmer). It will start to Blink confirming that you have a working microcontroller and hardware.

To change target device or family just change the #Chip Entry along with the Pin you have the LED on and recompile. it Really IS as Simple as that to get started in GCBASIC.

You can manually override GCBASIC and set every register, every flag, every BIT, every Configuration ‘Fuse’ and every vector if you wish, but why bother doing it upfront? Rather get your code working with the default settings and then adjust from there, if needed, as your confidence grows.

One final bit of advice, the IDE tool bar has a “View Demos” button, use it, there are examples of all of the most common programming challenges and many different devices which, along with the Help files, will answer most of your questions. The Forum is a friendly place too, so do not be shy to introduce yourself and ask for help.

Changes

Formal Release of GCBASIC Compiler v1.xx.xx

| Reference | Time Stamp |

|---|---|

ASCIIDOCs rendered |

2026-01-15 |

Master ToC information |

2025-10-03 |

Command Line Parameters

About the Command Line Parameters

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/NP] [/M:[Y/1 | N/0]] filename

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/WX] [/M:[Y/1 | N/0]] [/NP] filename

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/WX] [/M:[Y/1 | N/0]] [/S:Use.ini] [/NP] filename

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/WX] [/M:[Y/1 | N/0]] [/S:Use.ini] [/F[O]] [/NP] filename

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/WX] [/M:[Y/1 | N/0]] [/S:Use.ini] [/F[O]] [/NP] filename /DO

GCBASIC [/O:output.asm] [/A:assembler] [/P:programmer] [/K:{C|A}] [/H:[Y/1 | N/0]] [/V] [/L] [/WX] [/M:[Y/1 | N/0]] [/S:Use.ini] [/F[O]] [/NP] filename /AO

GCBASIC /version

| Switch | Description | Default |

|---|---|---|

|

Batch file used to call assembler(1). If |

The program will not be assembled |

|

Use .build folder for assembly operations. |

This is the Assembly Only switch. |

|

Exports the config bits automatically selected by the compiler to an output file called |

None |

|

Use .build folder for debugger operations. |

This is the DirectoryOutput switch. |

|

Used to bypass compilation when not needed, compiler will verify that config settings in the already compiled file match those required for the programmer. If not, a recompilation will be forced. Skip compilation if the hex file is up to date and has correct config. /F:x ( F or 0) to force a fresh compile regardless of what ini specifies. |

|

|

Used to bypass compilation and program only. Compiler will verify that config settings in the already compiled file match those required for the programmer. If not, a recompilation will be forced. |

|

|

Set the production, or not, of the hex output file. /H:1 is the default. To prevent production of the hex output file - use /H:0 |

The default is to produce the hex output file |

|

Keep original code in assembly output. |

No original code left in output. |

|

Show license and exit. |

- |

|

Mute the banner messages, or not. |

The default is to output banner messages |

|

Do not pause on errors. Use with IDEs. |

Pause when an error occurs, and wait for the user to press a key. |

|

Sets the name of the assembly file generated to |

Same name as the input file, but with a |

|

Batch file used to call programmer(1). This parameter is ignored if the program is not assembled. |

The program will not be downloaded. |

|

Load the settings from a specified file, rather than use the defaults. |

/S:use.ini |

|

Verbose mode — compiler gives more detailed information about its activities. |

- |

|

Force compiler to ensure all include files are valid. |

|

|

Show build date and version of the compiler. |

|

|

The file to compile. |

- |

(1) For the /A: and /P: switches, there are special options available. If

%FILENAME% is present, it will be replaced by the name of the .asm file.

%FN_NOEXT% will be replaced by the name of the .asm file but without an

extension, and %CHIPMODEL% will be replaced with the name of the chip.

The name of the chip will be the same as that on the chip data file.

A batch file to load the ASM from GCBASIC into MPASM. Command line should be like this:

C:\progra~1\microc~1\mpasms~1\MPASMWIN /c- /o- /q+ /l- /x- /w1 %code%.asm

A batch file to compile in GCBASIC then load the ASM from GCBASIC into GPASM. Command line should be like this:

gcbasic.exe %1 /NP /K:A /A:"..\gputils\bin\gpasm.exe %~d1%~p1%~n1.asm"

To instruct MAKEHEX.BAT to use GPASM. You have GPUTILS installed. The batch file should be edited as follows:

REM Create the ASM

gcbasic.exe /NP /K:A %1

REM Use GPASM piping to the GCB error log

gpasm.exe "%~d1%~p1%~n1.asm" -k -i -w1 >> errors.txt

To summarise, you can use any of the following:

gcbasic.exe filetocompile.gcb /A:GCASM /P:"icprog -L%FILENAME%" /V /O:compiled.asm

GCBASIC will compile the file, then assemble the program, and run this command:

`icprog -Lcompiled.hex`

You can also create/edit the gcbasic.ini file :

Assembler settings

Assembler = C:\Program Files\Microchip\MPASM Suite\mpasmwin

AssemblerParams = /c- /o- /q+ /l+ /x- /w1 "%FileName%"

Programmer settings

Programmer = C:\Program Files\WinPic\Winpic.exe

ProgrammerParams = /device=PIC%ChipModel% /p "%FileName%"

This example will use MPASM to assemble the program. It will run the program specified in the assembler = line, and give it these parameters:

`/c- /o- /q+ /l+ /x- /w1 "compiled.asm"`

Then, it will run the programmer, and give it these parameters when it calls it:

`/device=PIC16F88 /p "compiled.hex"`

%ChipModel% will get replaced with the chip you are using, so this the chip GCBASIC will pass to WinPIC.

Errors.txt

The compiler only produces the file errors.txt if there is an error. The creation of the errors.txt file makes it easier for IDEs to detect if the program compiled successfully - if the file was not produced then the IDE would be unalbe to present the error message to the user.

The file error.txt is always produced in the same folder as the compiler. Typically: C:\GCStudio\GCBASIC\Errors.txt

USE.INI

USE.INI is the provided setup file for the compiler. The name of use.ini is historic and of no relevance.

USE.INI is generally updated by using the PREFERENCES EDITOR.

USE.INI is self documenting and open use.ini in an editor will shown the full capabilities of setting file.

The details below show the self documentation in a typical use.ini

Preferences file for GC BASIC

Location: GCB install (or custom) dir

Documentation for the [gcbasic] section of the use.ini file

programmer = arduinouno - the currently selected available programmers

showprogresscounters = n - show percent values as compiler runs. requires Verbose = y

verbose = y - show verbose compiler information

preserve = n - preservice source program in ASM

warningsaserrors = n - treat Warnings from scripts as errors.

pauseaftercompile = n - pause after compiler. Do not do this with IDEs

flashonly = n - Flash the chip is source older that hex file

assembler = GCASM - currently selected Assembler

hexappendgcbmessage = n - appends a message in the HEX file

laxsyntax = n - use lax syntax when Y, the compiler will not check that reserved words

mutebanners = n - mutes the post compilation messages

evbs = n - show extra verbose compiler information, requires Verbose = y

nosummary = n - mutes almost all messages psot compilation

extendedverbosemessages = n - show even more verbose compiler information, requires Verbose = y

conditionaldebugfile = - creates CDF file

columnwidth = 180 - ASM width before wrapping

picasdebug = n - adds PIC-AS preprocessor message to .S file

datfileinspection = y - inspects DAT for memory validation

methodstructuredebug = n - show method structure start & end for validation

floatcapability = 1 - 1 = singles

- 2 = doubles

- 4 = longint

- 8 = uLongINT

compilerdebug = 0 - 1 = COMPILECALCADD

- 2 = VAR SET

- 4 = CALCOPS

- 8 = COMPILECALCMULT

- 16 = AUTOPINDIR

- 32 = ADRDX

- 64 = GCASM

Frequent errors

Frequent errors that may happen, from the initial creation of a program and onwards.

Strange timings: You declared an oscillator frequency, different from the oscillator actually attached to the micrcontroller.

No oscillator: Keep in mind that, besides the frequency, you must also set the type of oscillator, internal or external.

No GCBASIC frequency stated: If not declared in your source program - GCBASIC uses a preset frequency suitable for operating the microcontroller as the fastest practical.

External oscillators: It must be explicitly stated, if not stated GCBASIC will attempt to setup the internal oscillator.

Ports: GCBASIC will set the ports automatically but you may need to set the ports outputs or inputs when needed.

Analog levels: When applied on the ports defined as digital inputs. can cause current consumption in the input buffer, which is outside the device specifications. Beware.

Current drawn: Current taken from the microcontroller outputs, exceeding the maximum allowed (not all pins supply the same current). Beware of drawing to much current.

Watchdog Timer (WDT): The WDT is a useful timer. Enable to reset the microcontroller when processing can get stuck in a loop.

Interrupts: A badly controlled interrupt (in some cases) will prevent the execution of the entire program.

No action: The circuit is not powered.

Still no action: The microcontroller is not present or different from the device you expected.

Still no action: The microcontroller inserted incorrectly in the appropriate socket.

Cannot program: Incorrect programmer, Incorrect programmer parameters or circuit connections are incorrect.

Still Cannot program: Values of excessively incorrect circuit resistances.

Serial Communcations: The TX and RX pins of the serial port are exchanged, and/or the connections with the level converter, ttl / rs232 or ttl / usb.

Stlll no Serial Communcations: Serial speed, different from the one set in the circuit with which it is intended to communicate or vice versa.

No I2C/TWI: SDL and/or SCL pin exchanged on the I2C/TWI bus connection, and/or no pull-up resistors, and/or no common 0 voltage.

Incorrect timing: Calculation of any timings related to the frequency of the external oscillator, without taking into account the division by 4.

Strange Numeric Values: The variables declared are insufficient to contain the values to be processed.

A Glossary

ADC: analogue digital converter.

Negative power supply: reference to the common point of the circuit power supply, called circuit ground.

Alias: alternative name assigned to a pre-existing entity.

Array: variable able to handle numbers from 0 to 255.

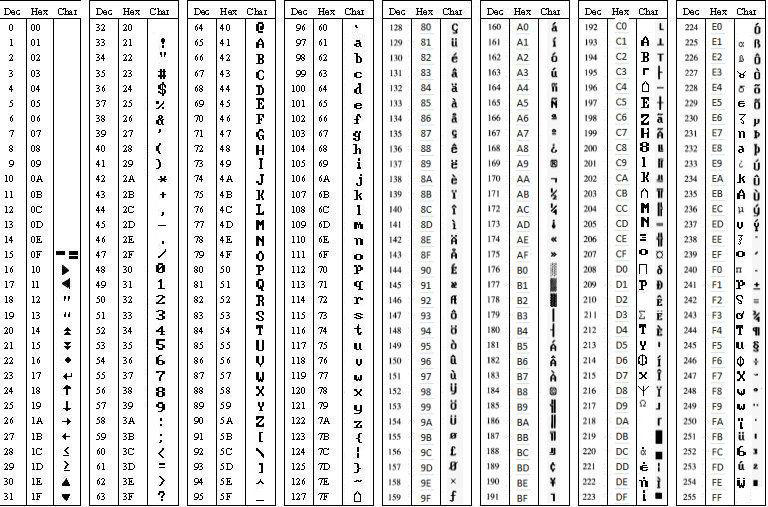

ASCII: acronym for the American Standard Code for information interchange. ASCII is a code for the representation of English characters as numbers.

Assembler: PC software application that converts assembly language into machine language.

Binary: numeric system with base 2, in which there are only two possible values for each digit#0 and 1.

Bit: the smallest element of computer memory. It is a single digit in a binary number (0 or 1). Bit is also a type of variable in GCBASIC.

Bitwise: dealing with bits and binary states instead of numbers or logic.

Byte: 8-bit variable, value from 0 to 255 (2^ 8-1). Is also a type of variable in GCBASIC.

Boolean: related to a combinatorial system designed by George Boole, which combines propositions with the logical operators AND, OR and IF THEN, except NOT.

CC: direct current.

Machine cycle: oscillator frequency / 4, for PIC (do not forget the PLL where present).

Code: the memory area in a PIC MCU or AVR that contains the program code.

Comment: reminder notes placed in the program.

Compiler: PC software application, which converts a high level language like BASIC into assembly language. In this guide "Compiler" refers to GCBASIC.

Compile-Time: acts during compilation, and is not executed as a command when the program is running on the microcontroller.

Constant: a name that stands for a value defined in the program. The value is replaced instead of the name when the program is compiled and assembled. It is not stored in RAM and cannot be changed during program execution.

D: Digital.

Data Space: is a memory space in a PIC or AVR that is intended for the storage of values (EEPROM memory on chip). Data is accessible in GCBASIC using the EpRead and EpWrite commands for reading and writing.

Dw: referring to a button or actions for the variation of any value, is intended as "decrease".

Debug: used to locate errors, to solve problems encountered when the program is run.

Decimal: numerical system with base 10, composed of 10 numbers from 0 to 9 inclusive. The "point" in a number with base 10 separates the whole part from the bottom to 1.

Device programmer: it is a tool that "writes" the code in machine language in the PIC or AVR microcontroller.

Directive: instruction intended for the compiler or assembler. It is not a command or a compiler statement.

Emdedded System: device controlled by a program, able to independently perform even complex functions, communicate with other similar devices and different architecture, with the personal computer, with a local network and directly via the web.

EPROM: erasable programmable read only memory.

EEPROM: a type of memory that stores data even in the absence of voltage, can be deleted and rewritten about 100,000 times.

Expression: a variable, constant, or combination that represents a stored or calculated value.

Firmware: program compiled and assembled, suitable to be loaded into the program memory, of a programmable device.

Fosc: oscillator frequency.

f.s.: full scale.

Hex: extension of the assembled file.

IDE: integrated development environment, software environment that acts as a code editor, and controls the various programming tools to implement software development.

Set: write in a register or variable, the condition required by the function to be performed.

I / O: input / output.

Integer: 32-bit variable, whose value varies from -32768 to 32767. Is also a type of variable in GCBASIC.

Interrupt: the use of a predefined signal or condition that interrupts normal execution, in favor of a special procedure with high priority.

Kbit / s: one thousand bits per second.

Keywords: keywords for GCBASIC.

Label: word that marks a position in a program.

Least-significant: in reference to binary numbers, a bit or groups of bits that include the "proper" bit. The rightmost bit or bit group, when a number is written in binary.

Assembly language: the programming language that corresponds more closely with machine language codes.

Voltage levels: in this guide we refer to TTL levels, so about 0 Volts for the low level and about 5 Volts or the Vcc of the microcontroller for the high level.

Level 0: equivalent to the low level.

Level 1: equivalent to the high level.

High level: presence of voltage, referring to the particular one is talking about.

Low level: no voltage, voltage close to zero.

Long: numeric entity composed of 32 binary bits, value from 0 to 4294967295 (2^32-1).Is also a type of variable in GCBASIC.

FLASH MEMORY: non-volatile memory, electrically rewritable numerous times, also called flash / rom.

Microchip: company that produces PIC microcontrollers, now also AVR

Mips: Mega instructions per second.

ms: milliseconds.

Modifier: keyword that somehow changes the interpretation or behavior associated with a command or variable that is written before or after the modifier.

Most-significant: in reference to binary numbers, the bit or group of bits that include the bit that indicates the maximum power of two. The leftmost bit or group of bits when a number is written in binary.

Nibble: a 4-bit binary quantity, can often be used to refer to the 4 most significant or least significant bits of 8-bit bytes. A single hexadecimal digit represents a binary nibble. It is not a variable type in GCBASIC.

ns: nanoseconds.

NC: not connected or, normally closed (depending on the context).

Overflow: the event that occurs when a value in a variable is increased beyond the capacity of the variable type, resulting in an incorrect result.

PC or pc: program counter.

Port: microcontroller port

Porta: Port a.

Portb: Port b.

Portc: Port c.

Portd: Port d.

Porte: Port e.

Pos or pos: postscaler.

Ps or ps: Prescaler

Programmer: you. The person who writes the program.

RAM: the memory area in a PIC MCU that is used to contain the variables. Access to RAM is faster than other memory areas, RAM values are lost when the power is turned off.

Register: an 8-bit memory location that performs a special function in a microcontroller. Registers that (Microchip calls SFR) are integrated in the microcontroller and their functions are described in the technical data sheet published for the device.

ROM: Read Only Memory (read-only memory, can only be written once).

Run-time: executed by the microcontroller when the program is executed (when it is running).

Save to context: save and restore in the context of the interrupt, important variables in the SFR registers.

SFR: registers with special function. Able to represent or process negative and positive numbers.

String: able to deal with number, letters and symbols. Is also a type of variable in GCBASIC.

TMR or tmr: timer.

TWI: I²C Bus.

Two’complement: (complement of 2) a system that allows negative numbers to be represented in binary.

Typecasting: specify a type of variable for the compiler.

Tp: test point.

Up: referred to a button or actions to change any value, it is intended as "increase".

Underflow: the event that occurs when a value in an unsigned variable decreases below zero (negative number), or when a variable is decreased below the limit value in a negative sense, resulting in an incorrect result.

Unsigned: only able to represent or transform positive numbers. Negative numbers are not valid in integer variables.

Variable: a name that is a synonym of a value that is stored in RAM and can be read and modified during program execution.

Word: a numeric entity composed of 16 binary bits. Value from 0 to 65535 (2^16-1)

V / I: voltage / current.

µs or us: microseconds.

Frequently Asked Questions

Why doesn’t anything come up when I run GCBASIC.exe?

GCBASIC IS a command line compiler. To compile a file, you can drag and drop it onto the GCBASIC.exe icon.

If you use an Integrated Development Environment (IDE) you can edit your program and press an ICON to send the program to the chip. Several are listed on the GCBASIC website.

The recommended IDE for Windows is GCCODE.

What Microchip PIC, Atmel AVR or LGT microcontrollers does GCBASIC support?

Hopefully, all 8 bit Microchip PIC, Atmel AVR and LGT microcontrollers and (those in the PIC10, PIC12, PIC16 and PIC18 families). If you find one that GCBASIC does not work with

properly, please post about it in the Compiler Problems section of the

GCBASIC forum.

Is GCBASIC case sensitive?

No! For example, Set, SET, set, SeT, etc are all treated exactly the

same way by GCBASIC.

Can I specify the bit of a variable to alter using another variable?

GCBASIC support bitwise assignments. As follows:

portc.0 = !porta.1

You can also use a shift function. As in other languages, by using the Shift Function FnLSL. AN example is:

MyVar = FnLSL( 1, BitNum)` is Equivalent to `MyVar = 1<<BitNum`

To set a bit of a port and to prevent glitches during operations, use #option volatile as folllows.

'add this option for a specific port.

#option volatile portc.0

'then in your code

portc.0 = !porta.1

To set a bit of a port or variable. Encapsulate it in the SetWith method, this also eliminates any glitches during the update, use this method.

SetWith(MyPORT, MyPORT OR FnLSL( 1, BitNum))

To clear a bit of a port, use this method.

MyPORT = MyPORT AND NOT FnLSL( 1, BitNum))

To set a bit within an array, use this method.

video_buffer_A1(video_adress) = video_buffer_A1(video_adress) OR FnLSL( 1, BitNum)

To set a bit within a variable, use this method.

Dim my_variable as byte

Dim my_bit_address_variable as byte

'example

my_variable = 0

my_bit_address_variable = 7

my_variable.my_bit_address_variable = 1 ' where 1 or 0 or any bit address is valid

'Sets bit 7 of my_variable therefore 128

Because it has not been thought of, or no-one has been able to implement it!

If there are any features that you would like to see in GCBASIC, please post them in the "Open Discussion" section of the GCBASIC forum. Or, if you can, have a go at adding the feature yourself!

When using an include file does this use lots of memory?

When using include files, for instance the <ds3231.h> include, if you are not using all the functions of the include file, GCBASIC knows not to include the unused functions within the user program when compiling.

If I am using the hardware I2C, does all the code related to hardware I2C still get compiled in the code?

GCBASIC only compiles functions and subroutines if they are called.

GCBASIC starts by compiling the main routine, then anything called from

there. Each time it finds a new subroutine that is called, it compiles

it and anything that it calls. If a subroutine is not needed, it does

not get compiled.

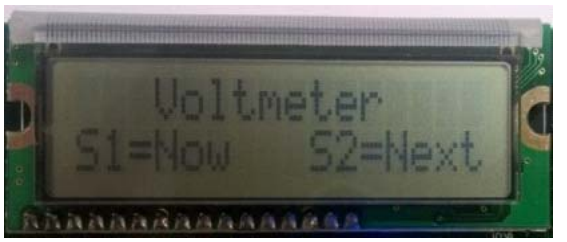

My LCD will not operate as expected?

Try adding. #define LCD_SPEED SLOW

This will slow the writing to the LCD.

Atmel AVR memory usage displayed is incorrect?

Atmel AVR memory values are specified in WORDS in GCBASIC. The GCBASIC compiler uses words, not bytes, for consistency between Microchip PIC and Atmel AVR microcontrollers. This keeps parts of the compiler simpler.

I cannot open the Window Help File?

See http://digital.ni.com/public.nsf/allkb/B59D2B24D624B823862575FC0056F3D0

How do I revert the FOR-NEXT loop to the Legacy FOR-NEXT method ?

Some background. In 2021 the GCBASIC compiler was updated to improve the operation of the FOR-NEXT loop. The improvement did increase the size of the ASM generated. The legacy FOR-NEXT loop had some major issues that included never ending loops, incorrect end loop and unexpected operations. This was all caused by the compiler, not the user, and in 2021 the compiler was updated to resolve these issues.

However, there is a risk that the new FOR-NEXT method causes 1) larger ASM that will not fit in small microcontrollers or 2) the new code does not operate as expected. In either case you can disable the new FOR-NEXT method by adding a constant as shown below. Adding this constant will revert the FOR-NEXT loop asm generated to the legacy method.

#DEFINE USELEGACYFORNEXT

Troubleshooting

| Problem | Common Causes | More Assistance |

|---|---|---|

Cannot compile a program |

There is an error in the program. Is GCBASIC complaining about a particular line of code? |

GCBASIC Forums |

GCBASIC has not been installed correctly - reinstall it. |

GCBASIC Forums |

|

There is a bug in GCBASIC |

Post on the GCBASIC Forums. Ensure you state the version of your compiler and attach your code as a ZIP. |

|

A program compiles and downloads fine, but will not run |

Oscillator not selected. |

GCBASIC Compiler Insights

This is the GCBASIC compiler insights section of the Help file. Please refer the sub-sections for details using the contents/folder view.

Compiler Insights

This section will provide some insights into what the compiler does

How does the compiler cope with read only registers in the Chip Family 12 range?

Within this chip range the Option register is a write only register. Reading the register is not permitted.

GCBASIC needs to update this when the user wants to change the configuration - the Sleep process is an example of a user change.

The compiler handles this by the creation of the Option_reg byte variable. This byte is created by the compiler to manage the required write process.

The Option_reg variable is a cache that compiler will create if any bits of option_reg have been set manually.

If the user changes any of the bits in a program, then the compiler will find any uses of the option instruction and insert a "movwf OPTION_REG" immediately before the option instruction to cache the value in the buffer.

If Option_reg bits aren’t set individually anywhere, then option_reg doesn’t get created, and nothing special is done with the option instruction.

Essentially the compiler maintains a special variable and manages the whole process without the user being aware.

How does the compiler cope with the TRIS register in the 10f products?

The compiler ensures that a TRIS cache matches the actual TRIS register. The TRIS cache is a byte variable called TRISIO. The TRISIO cache is required as TRIS is a write-only register.

All ports default to input ( where all TRIS bits to 1) on reset. Therefore, this is assumed to be the value 255.

TRISIO is updated when required by the user code and then used in the writing to the correct register.

The example user code and the associated assembly shows TRISIO cache in use. This method complies with datasheet.

User Code

'set as input dir gpio.0 in gpio0State = gpio.0 'set as output this will require TRIS GPIO to be set using the TRISIO cache. dir gpio.0 out gpio.0 = 1

ASM

;dir gpio.0 in bsf TRISIO,0 movf TRISIO,W tris GPIO ;gpio0State = gpio.0 clrf GPIO0STATE btfsc GPIO,0 incf GPIO0STATE,F ;dir gpio.0 out bcf TRISIO,0 movf TRISIO,W tris GPIO ;gpio.0 = 1 bsf GPIO,0

Anywhere that an individual TRIS bit is set/cleared by change the port direction, the bit in the cache is changed and then that gets written to the TRIS register.

Forcing the ASM to contain comments

It may be useful to force comments into the ASM file. The verbose mode of creating the ASM will include ALL the source program as comments but it may be useful to have specific comments in the ASM to aid the understanding of code or to support debugging.

To force an assembly comment use the following:

asm showdebug `comment`

Where the comment will be placed into the ASM file.

Example.

The source file contains the following, where the comment text is OSCCON type is 100

asm showdebug OSCCON type is 100

OSCCON1 = 0x60

The generated assembly will be as following - this assumes verbose mode is not selected.

INITSYS

;osccon type is 100

movlw 96

banksel OSCCON1

Constants, variables, subs and function and labels

GCBASIC uses a single namespace. A namespace is the set of names used to identify and refer to objects of various kinds. In GCBASIC these can be constants, variables, methods, and labels. Wwhere a label is a true label like the start of sub, function or macro. A namespace ensures that all of a given set of objects have unique names so that they can be identified. This organises constants, variables, methods, labels etc into a single list - the single namespace.

The namespace includes all libraries and source GCBASIC source files. If using MPASM this expands to chip specific INF file. If using PICAS then all of the PICAS toolchain including non-chip specific files. There are changes already in place to resolve this issue for PICAS as HEX and LINE are reserved with PICAS toolchain and these conflict with GCBASIC methods. These are automatically resolved by the GCBASIC compiler.

So, given that a constants, variables, methods, labels etc are number, the compiler does not know if that is a constant, a variable, a method, or a call to a label. Some are use cases using a constant called NORMAL follow.

NORMAL is defined as a constant with 0.

#1. Code segment

#DEFINE NORMAL 0 CALL Normal

The compiler will issue no error. The compiler will assume the following and will do as instructed. Call normal - this calls normal which has a value of 0

Resulting ASM

;CALL Normal call 0

#2. Code segment

#DEFINE NORMAL 0 CALL Normal()

The compiler will issue no error. The compiler will assume the following and will do as instructed. Call normal() - this calls normal which has a value of 0

Resulting ASM

;CALL Normal()

call 0

#3. Code segment

#DEFINE NORMAL 0 Normal

The compiler will issue an error message. The compiler will try to resolve the constant normal to a sub but it cannot as it is a value of 0.

Resulting ASM

;Normal

0 ;?F1L8S0I8?

#4. Code segment

#DEFINE NORMAL 0 Normal()

The compiler will issue an error message. The compiler will try to resolve the constant normal to a sub but it cannot as it is a value of 0.

Resulting ASM

;Normal()

0() ;?F1L8S0I8?

#5. Code segment

#DEFINE NORMAL 0 Normal = 1

The compiler will issue an error message. This tries to assign a value to the object.

Resulting ASM

;Normal = 1 0 = 1

#6. Code segment

#DEFINE NORMAL 0 Goto normal

The compiler will not issue an error message.

The compiler will goto (same for jmp) to the value of the object.

Resulting ASM

;goto Normal

goto 0

Compiler Control

The compiler can be controlled, in terms of the default startup library routines. This may be required to implement a specific control function, or, to disable a default startup behaviour.

Scenario #1:

You have a new LCD. The GCBASIC LCD routines fail to initialise. You want to write your own LCD initialise routine, but you want to ensure the GCBASIC standard INITLCD() does not operate before your own LCD initialise routine. How to do this?

Scenerio #2:

You want to write your own INITSYS routine. You can add your own routine to initialise the microntroller but the default INITSYS would always be called in the ASM.

In the first sceneria the approach would be to redirect the GCBASIC standard INITLCD() to myInitLCD using #define INITLCD myINITLCD. However, prior to the latest build, this would fail to work. The reason for the failure to redirect to your new routine is the #startup INITLCD directive. The #startup directive was essentially hard coded and all the #startup(s) could not be changed.

In the second scenerio the ASM call to INITSYS is also hard coded. And, you could trick the compiler to call your own initialisation routine but this was not easy and not intuitive.

The new build now supports the updating of the #startup(s) with your own routines, or even to cancel #startup(s).

Examples:

The compiler will search for all #startup(s) and update across all sources (libraries and includes). LCD.H is just an example.

#DEFINE INITLCD myINITLCD // This will change any reference in the LCD.h #startup INITLCD to #startup myINITLCD.

#DEFINE INITLCD // With no second parameter would cancel any #startup in LCD.h.

#DEFINE INITSYS myINITSYS // This will change the default INITSYS to myINITSYS.

#DEFINE INITSYS // This will remove the INITSYS from the initialisation of the microcontroller.

Example to change LCD initialisation

#DEFINE INITLCD myINITLCD

Sub myInitLCD

// do stuff

End Sub

Example to replace INITSYS

#DEFINE INITSYS // Cancel call

#STARTUP myInitSYS, 1 // New init routines, and set as highest priority

Sub myInitSYS

// do stuff

End Sub

Scripts can now change the #startup. You can add a script to change the behaviour dependent on a specific condition ( the existant of another constant).

In user program

#DEFINE LCD_OCULAR_OM1614

Supported within LCD.H

#SCRIPT

If Def( LCD_OCULAR_OM1614 ) Then

'Change INITLCD to specific Initialisation sub

INITLCD = INIT_OCULAR_OM1614_LCD

End if

#ENDSCRIPT

......

Sub INIT_OCULAR_OM1614_LCD

.. lots of code

End Sub

will generate ASM like this…

;Program_memory_page: 0

ORG 5

BASPROGRAMSTART

;Call initialisation routines

call INITSYS

call INIT_OCULAR_OM1614_LCD

;Start_of_the_main_program

This new capability to give you more control of the compiler.

For more help, see: #define, #startup

Libraries Overview

About Libraries

GCBASIC (as with most other microcontroller programming languages) supports libraries.

You can create you own device specific library, you are not limited to those shown below. If you create a new device specific library - please submit for inclusion in the next release via the GCBASIC forum.

Maintenance of these libraries is completed by the GCBASIC development team. If you wish to adapt these libraries you should create a local copy, edit and save within your development file structure. The development team may update these libraries as part of a release and we do not want you to lose your local changes.

To use a library, simple inlcude the following in your user code

#include <3PI.H> 'this will include the 3PI capabilities within your program

To use a local copy of a library, simple inlcude the following in your user code

#include "C:\mydev\library\3pi.h" 'this will include a local copy of the the 3PI capabilities within your program

GCBASIC supports the following device libraries.

| Library | Class | Usage |

|---|---|---|

3PI |

Polulu 3pi robot |

A library that interfaces the switch and the motors. |

47XXX_EERAM.H |

I2C EERAM memory |

A device specific library for the Microchip EERAM device classs |

ALPS-EC11 |

Rotary Encoder |

A device specific library for a rotary encoder. |

ADS7843 |

Touch Shield |

A library that interfaces with the ADS7843 touch screen. |

BME280 |

Temp, Humidity and Pressure sensor |

A library that interfaces with the BME280 and the BMP280 sensor. |

CHIPINO |

Shield |

A library that interfaces the Chipino board with Arduino like port addresses. |

DHT |

Temperature and Humidity |

A library that supports the DHT22 and the DHT11 Temperature and Humidity sensors. |

DS1307 |

Clock |

A library that supports the timer clock and NVRAM functions. |

DS1672 |

Clock |

A library that supports the timer clock and NVRAM functions. |

DS18B20 |

Temperature |

A library that supports the temperature functions. |

DS18SB0MultiPort |

Temperature |

A library that supports the temperature functions with devices attached to multiple ports. |

DS18S20 |

Temperature |

A library that supports the temperature functions. |

DS2482 |

Clock |

A library that supports the I2C to Dallas OneWire functions. |

DS3231 |

Clock |

A library that supports the timer clock and NVRAM functions. |

DUEMILANOVE |

Shield |

A library that interfaces the Duemilanove board with Arduino like port addresses. |

EMC1001 |

Temperature |

A library that supports the temperature functions and the other device capabilities. |

FRAM |

I2C Eeprom |

A library that supports memory functions. |

GETUSERID |

Microchip read ID |

A library that supports the identification of Microchip microcontrollers. |

EPD_EPD2In13 |

Graphical e-Paper display |

A core library for Graphical LCD support. |

EPD_EPD7in5 |

Graphical e-Paper display |

A core library for Graphical LCD support. |

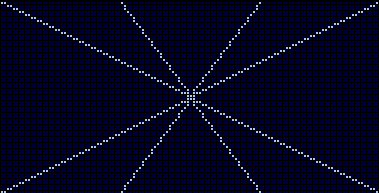

GLCD_ |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_HX8347 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ILI9340 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ILI9341 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ILI9481 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ILI9486L |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_NT7108C |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_IMAGESANDFONTS_ADDIN3 |

Graphical LCD |

A library to increase the capabilities of the Graphical LCDs. |

GLCD_KS0108 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_NEXTION |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_PCD8544 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_SH1106 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_SSD1289 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_SSD1306 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_SSD1331 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ST7735 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_ST7920 |

Graphical LCD |

A device specific library for an Graphical LCD. |

GLCD_T6963_64 |

Graphical T6963 LCD with 240 x 64 pixels |

A device specific library for an Graphical LCD. |

GLCD_T6963_128 |

Graphical T6963 LCD with 240 x 64 pixels |

A device specific library for an Graphical LCD. |

HEFLASH |

HEF Memory Driver |

A library that supports the HEF memory functions. |

HMC5883L |

Triple-axis Magnetometer |

A library that supports the magnetometer functions. |

HWI2C_ISR_HANDLER |

I2C Slave Driver |

A library that supports the use of a Microchip microcontroller as an I2C slave. |

HWI2C_MESSAGEINTERFACE |

I2C Slave |

A support library that supports the use of a Microchip microcontroller as an I2C slave. |

HWI2C_ISR_HANDLERKMODE |

I2C Slave Driver |

A library that supports the use of a Microchip microcontroller as an I2C slave. |

HWI2C_MESSAGEINTERFACEKMODE |

I2C Slave |

A support library that supports the use of a Microchip microcontroller as an I2C slave. |

I2CEEPROM |

I2C EEProm memory |

A library that supports memory functions. |

LCD2SERIALREDIRECT |

LCD to Serial Handler |

A library that supports the use of a serial and PC terminal as a psuedo LCD. |

LEGO-PF |

Lego Mindstorms shield |

A library that supports the Lego Mindstorms robot |

LEGO |

Lego Mindstorms shield |

A library that supports the Lego Mindstorms robot |

MATHS |

Maths routines |

A library that supports maths functions such as logs, power and atan. |

MAX6675 |

Temperature |

A library that supports the temperature functions. |

MAX7219_ledmatrix_driver |

LED 8*8 Matrix driver |

A library that supports the MAX7219 8*8 LED matrixes |

MCP23008 |

i2C to serial |

A library that supports the I2C to serial functions. |

MCP23017 |

i2C to serial |

A library that supports the I2C to serial functions. |

MCP4XXXDIGITALPOT |

Digital Pot |

A library that supports the MCPxxxx range of digital potentiometers. |

MCP7940N |

Clock |

A library that supports the timer clock and NVRAM functions. |

MILLIS |

Clock |

A library that supports the 1000ms timer event cycle. |

NUNCHUCK |

Game controller |

A library that supports the NunChuck game controller. |

PCA9685 |

PWM |

A device specific library for the 16channel PWM driver. See the demonstrations for example on usage. Support up to four devices via the I2C bus. |

PCF8574 |

GLCD |

A device specific library for an Graphical LCD. |

PCF85X3 |

Clock |

A library that supports the timer clock and alarms. |

SD |

SD Card |

A device specific library for an SD Card. |

SMT_Timers |

Signal Measurment Timer |

A library for Signal Measurment Timer for specific Microchip microcontrollers. |

SOFTSERIAL |

Serial |

A library for software serial. |

SOFTSERIALCH1 |

Serial |

A library for software serial. |

SOFTSERIALCH2 |

Serial |

A library for software serial. |

SOFTSERIALCH3 |

Serial |

A library for software serial. |

SONGLAY |

Music |

A library for play music. Supports QBASIC and RTTTL format. |

SONYREMOTE |

Infrared |

A library that supports the functions of a Sony remote control. |

SRF02 |

Distance Sensor |

A library that supports the SRF02 ultrasonic sensor. |

SRAM |

Memory devices |

A library that supports 23LC1024, 23LCV1024, 23LC1024, 23A1024, 23LCV512, 23LC512, 23A512, 23K256, 23A256, 23A640 or 23K640 devices |

SRF04 |

Distance Sensor |

A library that supports the SRF04 ultrasonic sensor. See GitHub demos here |

TEA5767 |

I2C Radio |

A library that supports the TEA5767 radio. |

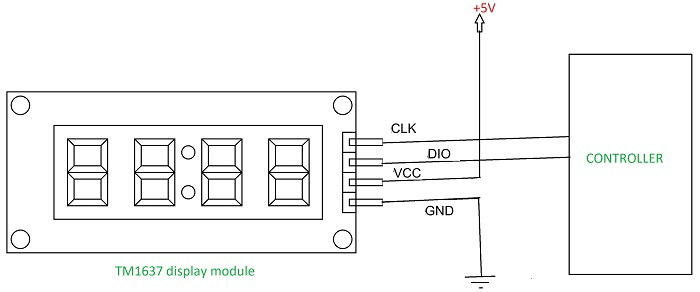

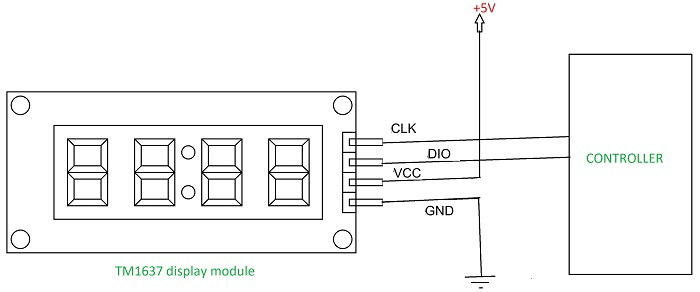

TM1637 |

7 Segment LED display |

A library that supports the TM1637 7-Segment LED displays |

TRIG2PLACES |

Maths functions |

A maths library that supports trignometry to two places. |

TRIG3PLACES |

Maths functions |

A maths library that supports trignometry to three places |

TRIG4PLACES |

Maths functions |

A maths library that supports trignometry to four places |

UNO_MEGA328P |

Shield |

A library that interfaces the shield with Arduino like port addresses. |

USB |

USB Supoort |

A library that interfaces the USB for 16f and 18f microcontrollers. |

GCBASIC supports the following core libraries. These libraries are automatically included in your user program therefore you do not need to use '#include' to access the libraries capabilities.

| Library | Class | Usage |

|---|---|---|

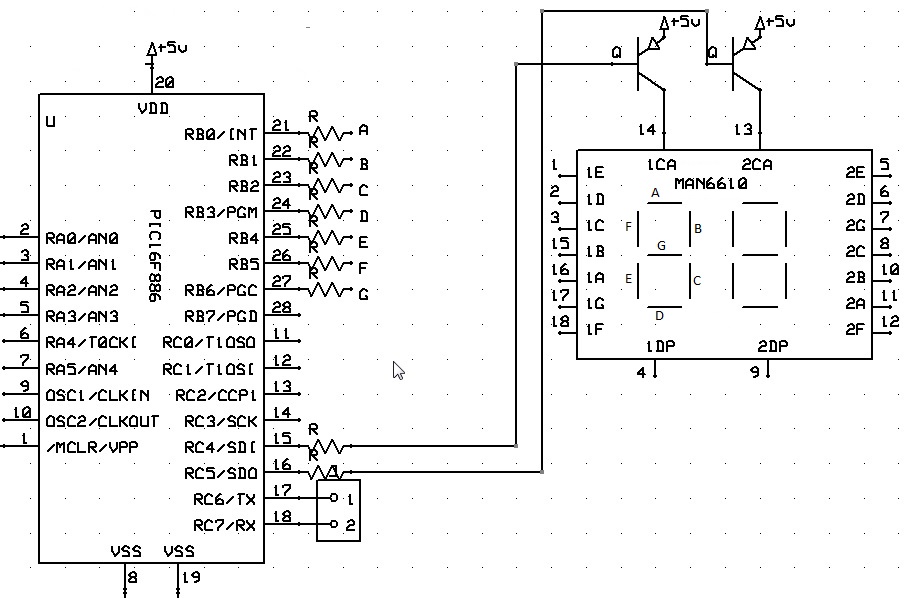

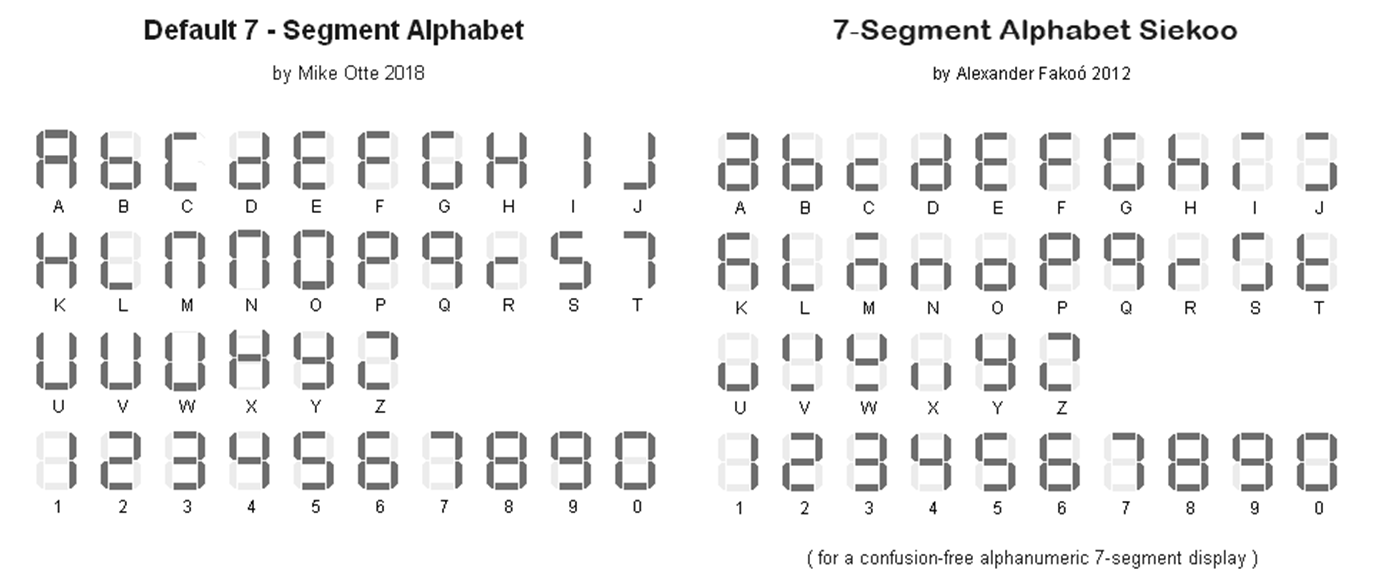

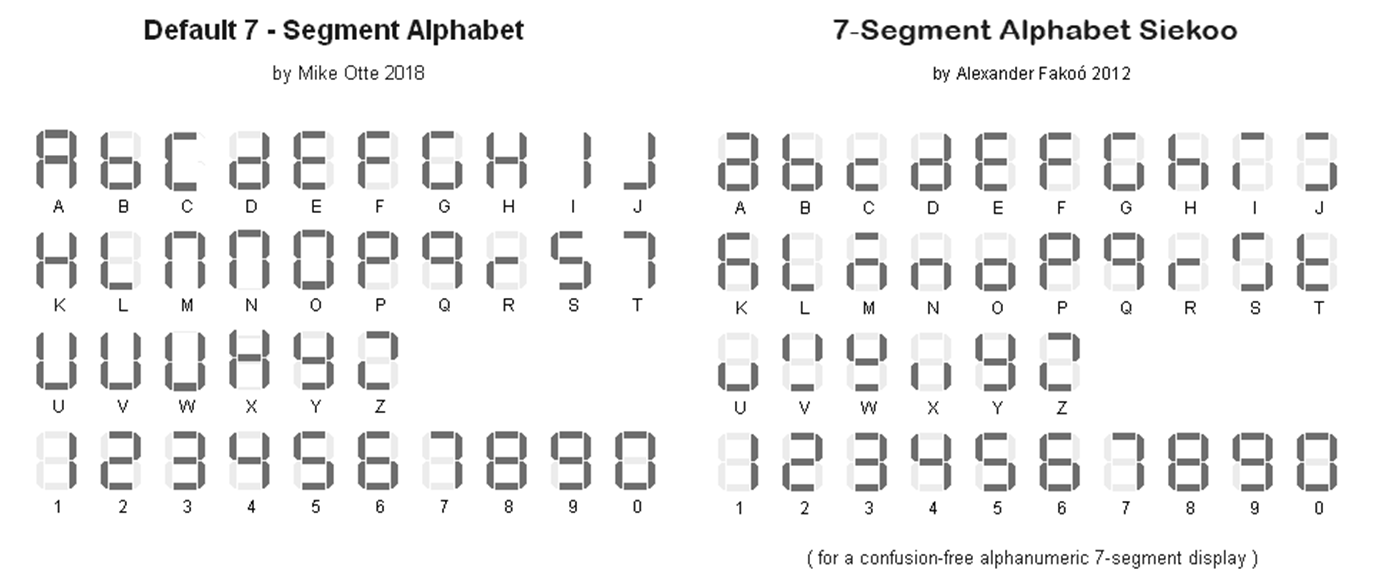

7SEGMENT |

7 Segment LED display |

A library that interfaces the device. See also TM1637a library. |

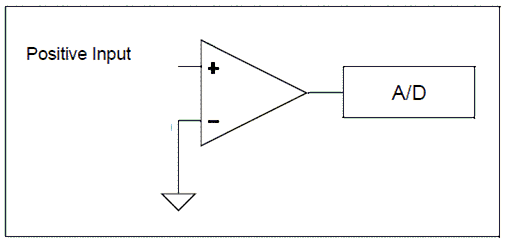

A-D |

Analog to Digital |

A library that supports the ADC functionality. |

EEPROM |

EEProm |

A library that supports I2C eeprom devices. |

HWI2C |

I2C |

A library that supports the MSSP and TWI hardware modules of I2C |

HWI2C2 |

I2C |

A library that supports the MSSP and TWI hardware modules of I2C on channel two |

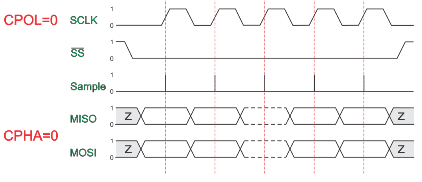

HWSPI |

SPI |

A library that supports the MSSP and TWI hardware modules of SPI |

I2C |

I2C |

A library that supports software I2C |

KEYPAD |

KeyPad |

A library that supports a keypad. |

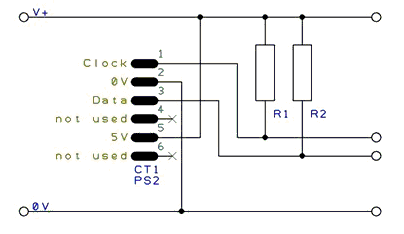

PS2 |

I2C |

A library that supports keyboard functionality |

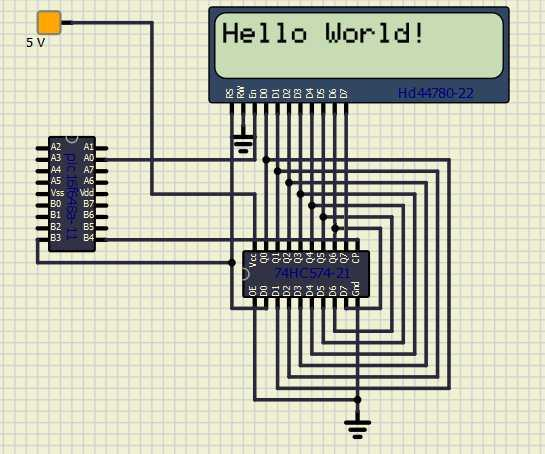

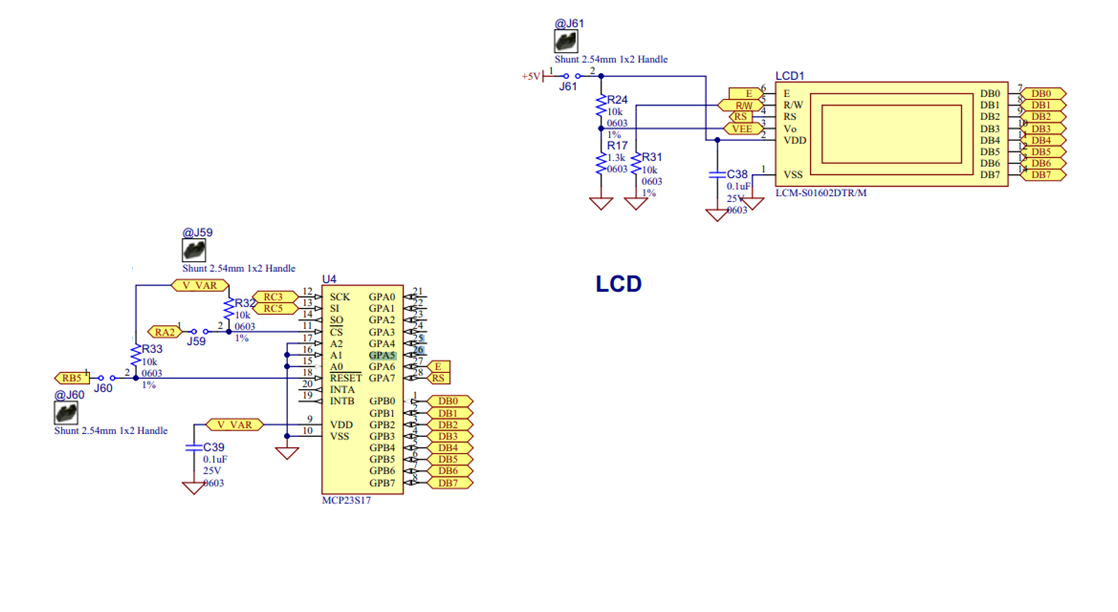

LCD |

LCD |

A library that supports LCD functionality, library supports many different communications methods. |

PWM |

Pulse Width Modulation |

A library supports PWM functionality. |

RANDOM |

Random Numbers |

A library supports random number functionality. |

REMOTE |

Infrared |

A library that supports the functions of a NEC remote control. |

RS232 |

Serial |

A library for serial communications. |

SOUND |

Tones |

A library for sound and tone generation |

STDBASIC |

Utility Functions |

The library that contains many of the utility methods. |

STRING |

String |

The library that contains the string methods. |

SYSTEM |

System |

The library that contains the system methods. |

TIMER |

Timers |

The library that contains the timer methods. |

USART |

Serial |

The library that contains the hardware serial methods that use the MSSP or AVR equivilent hardware module. |

XPT2046 |

Touch Shield |

A library that interfaces with the APT2026 and the ADS7843 touch sensors. |

Acknowledgements

Developers and Contributors:

Hugh Considine - Main developer of GCBASIC

Stefano Bonomi - Two-wire LCD subroutines

Geordie Millar - Swap and Swap4 subroutines

Jacques Nilo - HEFM and help file conversion to asciidoc

Finn Stokes - 8-bit multiply routine, program memory access code

Evan Venn - Utilities, revised I2C routines, this help file and generally everything else!

Translation Contributors:

Stefano Delfiore - Italian

Pablo Curvelo - Spanish

Murat Inceer - Turkish

Other Contributors:

Russ Hensel - GCBASIC Notes.

Chuck Hellebuyck - His documentation for the GLCD and other pieces, see http://www.elproducts.com.

Frank Steinberg - GCode IDE for GCBASIC.

Alexy T. - SynWrite IDE used for GCB IDE, see http://www.uvviewsoft.com/synwrite

Thomas Henry for the Select Case and the Sine Table examples.

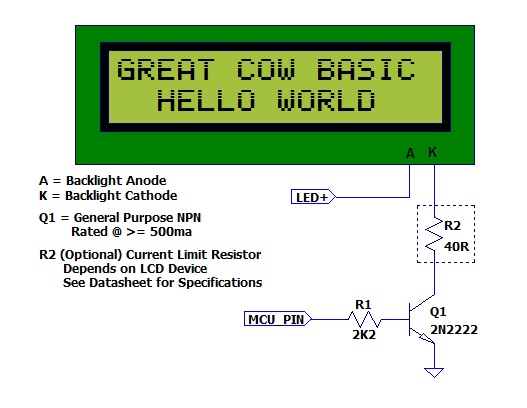

William Roth for the LCD code and supporting diagrams.

Theo Loermans for the revised LCD sections and the serial library.

Chris Roper for the bitwise methods including the library including FnEquBit, FnNotBit, FnlslBit, FnlsrBit, SetWith and 47xxx.

Jberg2024 for the adaption of the Software Serial routines to improve usage.

Angel Mier for the USB driver installation

Conversion of asciidoctor documentation files:

See the asciidoctor Web site and the support forum.

Tricks and Tips

This is a collation of tricks and tips that may be useful to you.

RAM, variables and resets

TIP: RAM, variables and resets

When you define a variable it will be mapped to a RAM location. As you develop your solution your should always do the following to ensure the variable are initialised correctly.

-

Always initialise variables to a known state

A variable will not show up in the ASM source code unless it is used somewhere in code.

Adding Variable = 0 will assure that the variable is initialised and will show up in the ASM.

This is very useful for troubleshooting.

This is essential when debugging ASM to look at variables that are defined using "EQU".

If you do not initialise or use the variable then the variable will not be shown in the EQU list of variables.

So, initialise all your variables.

-

Always power cycle the microcontroller after programming

A soft reset when debugging/testing/programming will not reset the RAM to a known state.

This is essential when debugging ASM to look at variables that are defined using "EQU".

A soft reset does not change the contents of RAM.

Where a hard reset reverts ram back to an undefined /random state!

So, a power cycle is good practice.

TRICK: Reverting the FOR-NEXT loop to the Legacy FOR-NEXT method ?

Why do this? To reduce the PROGMEM size. But, you must assure yourself that the loop variable cannot overflow as the legacy FOR-NEXT does not prevent an overflow of the loop variable.

Some background. In 2021 the GCBASIC compiler was updated to improve the operation of the FOR-NEXT loop. The improvement did increase the size of the ASM generated. The legacy FOR-NEXT loop had some major issues that included never ending loops, incorrect end loop and unexpected operations. This was all caused by the compiler, not the user, and in 2021 the compiler was updated to resolve these issues.

However, there is a risk that the new FOR-NEXT method causes 1) larger ASM that will not fit in small microcontrollers or 2) the new code does not operate as expected. In either case you can disable the new FOR-NEXT method by adding a constant as shown below. Adding this constant will revert the FOR-NEXT loop asm generated to the legacy method.

#DEFINE USELEGACYFORNEXT

TRICK: How to change the compilers behaviour when the compiler states a capability is not available when I know it is ?

The compiler is issuing an error message that a EEPROM, HEF, SAF, PWM16 or hardware USART is not available… but, it is.

This is caused by the microcontroller DAT file. The microcontroller DAT file is missing key information that informs the compiler that a specific capability is available. This information was added to prevent silent failures where you could use a capability when it is not available.

The compiler thinks your microcontroller does not have the selected capability. Simply use the table below to resolve. Adding the constant defined to your source program.

Then, let us know via the Forum so we can correct the source microcontroller DAT file.

| EEPROM |

|

| HEF |

|

| SAF |

|

| PWM16 |

|

| USART hardware |

|

TRICK: How do I create a minimal ASM source with no config and/or initsys?

Very easy.

Simple add two #OPTION statements.

#OPTION UserCodeOnly ENTERBOOTLOADER: This will instruct the compiler to NOT call the INITSYS() method.

And, to jump to a label.

The label is mandated. The label specified will be included in the ASM generated.

#OPTION NoConfig This will instruct the compiler to NOT add the microcontroller specific config statements.

Example:

#chip 16f877a, 4

#OPTION Explicit

#OPTION UserCodeOnly ENTERBOOTLOADER:

#OPTION NoConfig

ENTERBOOTLOADER:

The example above yields the following asm. Comment lines have been removed for clarity.

LIST p=16F877A, r=DEC

#include <P16F877A.inc>

;Vectors

ORG 0

pagesel ENTERBOOTLOADER

goto ENTERBOOTLOADER

;ORG 5

ENTERBOOTLOADER

;ORG 2048

;ORG 4096

;ORG 6144

END

TIP: PPS and multiple USARTs

You can set up multiple pins to simultaneously operate as a peripheral output on microcontrollers with Peripheral Pin Select (PPS).

PPS microcontrollers can set up to simultaneously output specific modules.

The example below shows the method to output two TX ports.

Hardware Serial (TX1) data will now be output on both B.6 and C.6

Sub InitPPS

'Module: UART pin directions

Dir PORTC.6 Out ' Make TX1 pin an output

Dir PORTB.6 Out ' Make TX1 pin an output

'Module: UART1 to two ports

RC6PPS = 0x0020 'TX1 > RC6

RB6PPS = 0x0020 'TX1 > RB6

End Sub

UNO as ISP programmer

So, you have brought some ATtiny88 breakout boards online. They are advertised as Nano equivalents but are inferior to the Nano in having low RAM (512 bytes vs 2048) and missing some other features. Specifically the lack of a USB comport for programming.

The ATtiny88 USB interface only works in Arduino IDE with some tweaking, and, you are not in the mood for learning how to write sketches after being in the GCB environment for years.

This is an all-in-one tutorial for programming the ATtiny88 via AVRdude using GCB.

|

Note

|

The only baud rate that works is 19200. Every other baud rate failed in testing |

The process described will create a new programmer entry in the GCB Programmer Options to fully automate the compile & program progress.

|

Note

|

This refers to an ATtiny88 but you can use this method for many AVRs which used in conjunction with AvrDude. |

The Process

-

Obtain an Arduino UNO or mega. Upload this hex file to convert the UNO into an ISP programmer or follow steps 2 -5 below.

-

Download the Arduino IDE software. This is used to upload a sketch to the UNO that converts it into an ISP programmer.

-

Connect the UNO to your PC via USB. In Arduino IDE goto Tools → Set board and select "Arduino UNO". Select the correct com port for the Arduino Uno as show in device manager.

-

Goto file → examples → ArduinoISP to select the sketch that will convert the UNO to an ISP programmer. I found a better(?) working version at adafruit. Simply copy all the text from this link into a new sketch https://raw.githubusercontent.com/adafruit/ArduinoISP/master/ArduinoISP.ino (or download the ino file attached and open it in Arduino IDE) and goto step 5

-

Click upload and confirm the sketch uploaded correctly by checking the status window at the bottom of the Arduino IDE

-

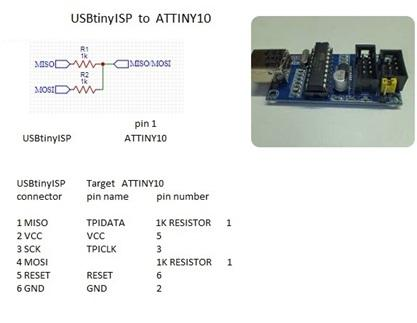

Build a cable to connect the ISP headers on the UNO and target (ATtiny88) board as described below. Search online for the UNO ISP header pinout, the ISP header happens to be labelled underneath the ATtiny88 breakout board.

-

Connect pin 10 of the UNO to the reset pin on target ISP header

-

Connect VCC to VCC, MOSI to MOSI, MISO to MISO, GND to GND, SCK to SCK.

-

Open Synwrite → "IDE tools" → "GCB tools" → "Edit Programmer preferences", or, in GCStudio "Edit Programmer preferences"

-

Click "add" and a program editor window opens

-

Enter name Arduino as ISP or similar

-

In the "Use if" box paste DEF(AVR)

-

In the "File" box paste %instdir%..\avrdude\avrdude.exe

-

In the "command line parameters" paste -c avrisp -p t88 -P %Port% -b 19200 -U flash:w:"%FileName%":a

-

Select the com port that corresponds to the connected UNO port

-

Click ok

Enter the sample code here into GCB IDE

#chip tiny88, 12

dir portd.0 out

Do

set portd.0 on

wait 500 ms

set portd.0 off

wait 500 ms

Loop

Now you can select "Hex/Flash" to upload the code to the Attiny88. If all goes well the LED should blink on and off every second

Microcontroller Fundamentals

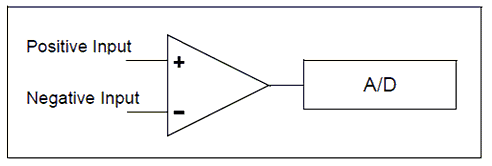

Inputs/Outputs

About Inputs and Outputs

Most general purpose pins on a microcontroller can function in one of two modes: input mode, or output mode.

When acting as an input, the general purpose input/output pin will be placed in a high impedance state. The microcontroller will then sense the general purpose input/output pin, and the program can read the state of the general purpose input/output pin and make decisions based on it.

When in output mode, the microcontroller will connect the general purpose input/output pin to either Vcc (the positive supply), or Vss (ground, or the negative supply). The program can then set the state of the general purpose input/output pin to either high or low.

GCBASIC will attempt to determine the direction of each general purpose input/output pin, and set it appropriately, when possible. GCBASIC will try to set the direction of the general purpose input/output pin. However, if the general purpose input/output pin is read from and written to in your program, then the general purpose input/output pin must be configured to input or output mode by the program, using the appropriate Dir commands.

Example of dir commands.

'The port address is microcontroller specific. Portx.x is a general case for PICs and AVRs

dir portb.0 in

dir portb.1 out

'The port address is microcontroller specific. gpiox.x is a general case for some PICs

dir gpio.0 in

dir gpio.1 Out

'Set the whole port as an output

dir portb out

dir gpio out

'Set the whole port as an input

dir portc in

dir gpio in

Microchip specifics for read/write operations

For the specific ports and general purpose input/output pins available for a specific microcontroller please refer to the datasheet.

| Port | Purpose | Example |

|---|---|---|

PORTx maps to the microcontrollers digital pins 0 to 7. Where x can be a,b,c,d,e,f or g |

Read: PORTx the port data register for a read operation. |

uservar=PORTA uservar=PORTA.1 |

PORTx maps to microcontrollers digital pins 0 to 7. Where x can be a,b,c,d,e,f or g |

Write: PORTx the port data register for a write operation, and, where LATx is not required as GCBASIC will implement LATx when needed. See Option NoLatch for more information on LAT registers and how to disable this automatic function. |

PORTA=255 PORTA.1=1 |

To read a general purpose input/output pin, you need to ensure the direction is correct DIR Portx IN is set (default is IN) or a specific set of port bits.

Where uservar = PORTx.n can be used.

Examples:

uservar = PORTb.0

uservar = PORTb

To write to a general purpose input/output pin, you need to ensure the direction is correct DIR Portx OUT for port or a specific set of port bits.

Where PORTx.n = uservar can be used.

Examples:

PORTb.0 = uservar

PORTb = uservar

ATMEL specifics for read/write operations

Using a Mega328p as a general the following provides insights for the AVR devices. For the specific ports and general purpose input/output pins available for a specific microcontroller please refer to the datasheet.

| Port | Write operation | Read operation |

|---|---|---|

PORTD maps to Mega328p (and, the AVR microcontrollers) digital pins 0 to 7 |

PORTD - The Port D Data Register - write operation (a read operation to a port will provide the pull-up status) |

PIND - The Port D Input Pins Register - read only |

PORTB maps to Mega328p (and, the AVR microcontrollers) digital pins 8 to 13. The two high bits (6 & 7) map to the crystal pins and are not usable |

PORTB - The Port B Data Register - write operation (a read operation to a port will provide the pull-up status) |

PINB - The Port B Input Pins Register - read only |

PORTC maps to Mega328p (and, the AVR microcontrollers) analog pins 0 to 5. Pins 6 & 7 are only accessible on the Mega328p (and, the AVR microcontrollers) Mini |

PORTC - The Port C Data Register - write operation (a read operation to a port will provide the pull-up status) |

PINC - The Port C Input Pins Register - read only |

To read a general purpose input/output pin, you need to ensure the direction is correct DIR Portx IN is set (default is IN) or a specific set of port bits.

Where uservar = PINx.n can be used and therefore to read data port use uservar = PINx.

Examples:

uservar = PINb.0

uservar = PINb

To write to a general purpose input/output pin you need to ensure the direction is correct DIR Portx OUT for port or a specific set of port bits.

Where PORTx.n = uservar can be used and therefore to write to a data port use PORTx = uservar.

Examples:

PORTb.0 = uservar

PORTb = uservar

Setting Ports and Port.bit

You can set a port as shown above with a variable, or, you can set with a constant or any combination using the bitwise and logical operators.

#define InitStateofPort 0b11110000

PORTb = InitStateofPort 'will unconditionally set bits 4:7

PORTb = 0b11110000 'will unconditionally set bits 4:7

PORTb = uservar OR 0b11110000 'will OR bits 4:7 to ensure bits 4:7 are set

The following is also valid - read a port.bit and then set port.bit with a variable or port value. As shown below.

dir portb out

portb.0 = NOT portb.0

The user code above may cause issues with glitches when the read and write operations occurs. Let us look at the generated assembler.

;portb.0 = NOT portb.0

banksel SYSTEMP1

clrf SysTemp1

btfsc PORTB,0

incf SysTemp1,F

comf SysTemp1,F

bcf PORTB,0

btfsc SysTemp1,0

bsf PORTB,0

To resolve any glitches add #option Volatile to your user code.

#option Volatile portb.0

dir portb out

portb.0 = NOT portb.0

This option provides the following assembler resolving the glitch issue.

;portb.0 = NOT portb.0

banksel SYSTEMP1

clrf SysTemp1

btfsc PORTB,0

incf SysTemp1,F

comf SysTemp1,F

btfsc SysTemp1,0

bsf PORTB,0

btfss SysTemp1,0

bcf PORTB,0

See also Dir, #Option Volatile

Configuration

About Microcontroller Configuration

For PICs

This section applies to Microchip PIC microcontrollers. For AVR and LGT microcontrollers see the sections below.

Every Microchip PIC has a CONFIG word. This is an area of memory on the chip that stores settings which govern the operation of the chip.

The following asects of the chip are governed by the CONFIG word:

-

Oscillator selection - will the chip run from an internal oscillator, or is an external one attached?

-

Automatic resets - should the chip reset if the power drops too low? If it detects it is running the same piece of code over and over?

-

Code protection - what areas of memory must be kept hidden once written to?

-

Pin usage - which pins are available for programming, resetting the chip, or emitting PWM signals?

The exact configuration settings vary amongst chips. To find out a list of valid settings, please consult the datasheet for the microcontrollers that you wish to use.

This can all be rather confusing - hence, GCBASIC will automatically set some config settings, unless told otherwise:

-

Low Voltage Programming (LVP) is turned off. This enables the PGM pin (usually B3 or B4) to be used as a normal I/O pin.

-

Watchdog Timer (WDT) is turned off. The WDT resets the chip if it runs the same piece of code over and over - this can cause trouble with some of the longer delay routines in GCBASIC.

-

Master Clear (MCLR) is disabled where possible. On many newer chips this allows the MCLR pin (often PORTA.5) to be used as a standard input port. It also removes the need for a pull-up resistor on the MCLR pin.

-

An oscillator mode will be selected, based on the following rules:

-

If the microcontroller has an internal oscillator, and the internal oscillator is capable of generating the speed specified in the #chip line, then the internal oscillator will be used.

-

If the clock speed is over 4 Mhz, the external HS oscillator is selected

-

If the clock speed is 4 MHz or less, then the external XT oscillator mode is selected.

-

Note that these settings can easily be individually overridden whenever needed. For example, if the Watchdog Timer is needed, adding the line

#config WDT = ON

This will enable the watchdog timer, without affecting any other configuration settings.

For AVR

This section applies to Atmel AVR microcontrollers. Generally, Atmel AVR microcontrollers do have a similar configuration settings, but they are controlled through "Configuration Fuses". GCBASIC cannot set these - you MUST use the programmer software.

The exception to the general case are the ATTiny4-5-9-10 and ATTiny102-104. These microcontrollers have software selectable frequencies for the following frequencies:

ChipMHz 8 ChipMHz 4 ChipMHz 2 ChipMHz 1 ChipMHz 0.5 ChipMHz 0.25 ChipMHz 0.125 ChipMHz 0.0625 ChipMHz 0.03125

Therefore, you can use ( an example )

#chip tiny10, 0.25

For LGT

This section applies to LGT microcontrollers.

All LGT microcontroller have software selectable frequencies for the following frequencies:

ChipMHz 8 ChipMHz 4 ChipMHz 2 ChipMHz 1 ChipMHz 0.5 ChipMHz 0.25 ChipMHz 0.125 ChipMHz 0.0625 ChipMHz 0.03125

Therefore, you can use ( an example )

#chip #chip LGT8F328P, 0.25

Using Configuration

For PICs only.

Once the necessary CONFIG options have been determined, adding them to the program is easy. On a new line type "#config" and then list the desired options separated by commas, such as in this line:

#config OSC = RC, BODEN = OFF

GCBASIC also supports this format on 10/12/16 series chips:

#config INTOSC_OSC_NOCLKOUT, BODEN_OFF

However, for upwards compatibility with 18F chips, you should use the = style config settings.

It is possible to have several #config lines in a program - for instance, one in the main program, and one in each of several #include files. However, care must then be taken to ensure that the settings in one file do not conflict with those in another.

For more help, see #config Directive

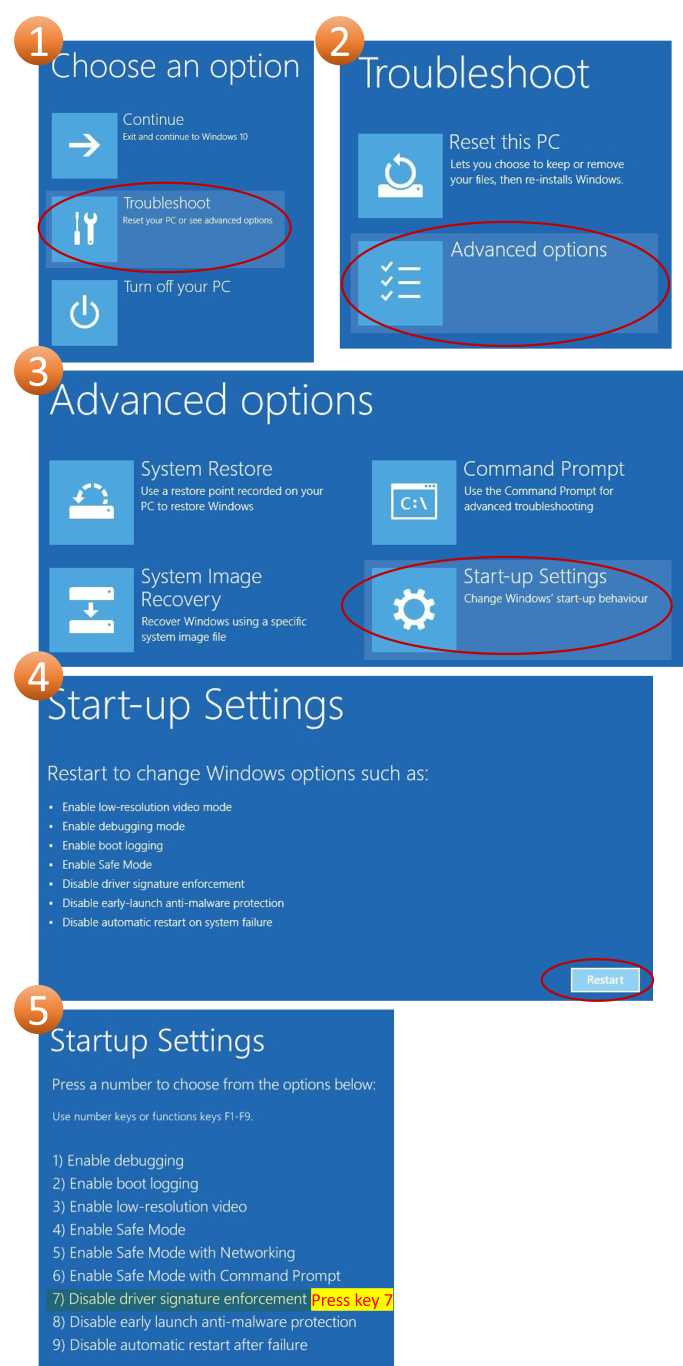

USB Drivers Installer

|

Warning

|

Installing the USB driver is only required when using the GCBASIC USB library. |

Description:

The drivers for windows x86 and x64 correspond to the USB LIBKWIN capability of GCBasic for supported PIC microcontrollers.

For security reasons, in Microsoft windows for a driver to be installed, it is necessary that it be digitally signed by Microsoft.

Microsoft did make a special “Test” mode for developers to install MANUALLY unsigned drivers for debug and testing, being a technical advanced and not user-friendly procedure; at the same time the windows developers make efforts to disable the capability of doing this in an automated fashion by the concerns of being used as a vulnerability of the operating system.

This scenario will make installing test drivers difficult and frustrating for the uninitiated, at the same time for a useful Hobby project it will be not practical to make end users to take all this drama.

This driver installer method resolves the constraints imposed by the Windows operating system, and, therefore will allow you to install the drivers in the easiest way possible, almost like any driver of a well-known company.

Usage:

|

Warning

|

The installer will reboot the system without notice. Please close all programs and save any work you have open before begin whit the driver install. |

1 - Open the installer, it will request admin rights.

2 - Navigate thru the wizard to automatically extract the driver files (there aren’t any options to select).

3 - At the end of the wizard, after you click the exit button, the system will restart automatically

|

Warning

|

In the case where your computer has Secure Boot enabled, the installer will advise you of extra steps needed after reboot, at the end of this page you will find a graphic reflecting those steeps and what elements you need to select. |

4 - After restart and login in to your user account, a window will inform you that the driver is not signed and you will be asked if you want to install the driver, please allow it.

5 - when the driver has been installed, the computer will restart automatically.

Secure Boot Enabled, Boot menu steps

USB Driver details

The driver uses the following USB flags.

USB_VID 0x1209

USB_PID 0x2006

USB_REV 0x0000

For others, need to modify and recompile the USB library.

USB_PRODUCT_NAME and USB_VENDOR_NAME can change without problem (windows device manager will show the name reported by the hardware not the driver

Tested on (but not limited to)

Windows 11 pro x64 secureboot disabled, os build Dev 21H2 22000.194

Windows 11 pro x64 secureboot enabled, os build Dev rs_prerelease 22458.1000

Windows 10 pro x64 secureboot disabled, os build stable 20H2 19042.867

Windows 7 pro x86 secureboot disabled, os service pack 1 build 6.1.7601

Variables

Data Types

This section discusses the different types and sizes of data variables used by GCBASIC, and how they are interpreted or handled by GCBASIC methods.

The section also provides an insight of which type of variable to use and when.

What variable sizes are suported by GCBASIC?

GCBASIC implements support for Bit, Byte, Word, Integer and Long Variable Types, all of which are described below.

Supported variables are Bit (1 Bit), Byte (8 Bit), Word (16 Bit), Long (32 Bit). GCBASIC does not support decimal numbers.

Bit is used as a Flag or a Port Pin and has two states which may be:

ON or OFF

TRUE or FALSE

HIGH or LOW

1 or 0

SET or RESET

other complementary states depending on how your application interprets and handles the data.

Byte is the most common size in 8 Bit devices and could represent a Number, an ASCII Character, a Port, two Nibbles (as used by Hex or BCD number systems), an Internal Register, an 8 bit Variable or any user defined collection of to eight Bits such as a group of flags.

Word is normally used for its Numeric value. 16 Bits will allow it to store Numbers from Zero to 65535 which is large enough to store the product of any two 8 bit Bytes without overflowing. However, it is not confined to being used as a numeric value. A Word may be used in any manner that your application needs depending on how it interprets the 16 Bits of data. Examples may be a memory address or a data pointer.

-

Note: The Word size of a device (as opposed to the Word Type above) is a representation of the number of Bits that it can manipulate simultaneously by the chip. The number of Bits for PIC and AVR Microcontrolers supported by GCBASIC are 8 Bits and so they are considered to have an 8 Bit Word.*

Long is for situations where Values exceeding 65535 have to be handled and has a range of zero to 4294967295 (2^32-1). It is rarely used in 8 Bit devices but is invaluable on the rare occasions that it is needed. The Millis() is an example that uses the Long Data Type to handle time periods of up to 50 days.

All of the above can be considered to be Integer Values of varying magnitude as they can hold non Fractional Positive Whole Numbers, but try not to confuse Integer Values with the Integer Variable Type, they are complementary but separate concepts as you will see below.

An integer is a whole number (not a fractional number) that can be Positive, Negative, or Zero.

In your application there may be a need to be able represent Negative Numbers in our variables and that is where the GCBASIC Integer Variable Type is useful. An Integer Variable is similar to the Word Variable as they are both 16 bits. The difference how the GCBASIC compiler interprets the data bits that it contains.

The compiler will treat a Word Variable Type as a Variable that can store the values 0 < 65535 but it will see the Integer Variable Type as a Variable that can store values of -32768 < 0 <32767.

Variable size

Each type of variable is defined in various bit lengths, in this case GCBASIC these are:

Byte 8 Bit

Integer 16 Bit

Word 16 Bit

Long 32 Bit

All four of the above are number types are true Integers. In that they are representations of a integer non fractional number as follows:

8 Bit - an 8 Bit number can be in the range of 0 to 255

16 Bit - a 16 Bit number can be in the range of 0 to 65535

32 Bit - a 32 Bit number can be in the range of 0 to 4294967295 (2^32-1)

But, they can only represent positive numbers. In Mathematics there is a need for an Integer that can be Positive, Negative, or Zero. Note that Zero is always a Positive Whole Number.

Two’s Complement

To take the Two’s Complement of a number it is inverted then incremented:

MyVar = NOT MyVar + 1

The increment, of adding 1, has two effects, it avoids the possible creation of a negative zero as a value of 1000000 would be seen as -128 and it allows subtraction to be achieved through addition.

If MyVar contained a value of 1 the 8 Bit representation would be:

00000001

The NOT will make it

11111110

Note that the Most significant Bit is now 1 so as a signed value it is negative.

The increment will result in a value of:

11111111

So Minus one using an 8 Bit representation in Two’s Complement notation is 11111111

Let’s test it by adding -1 to plus 3

11111111 -1

00000011 + 3

==============

00000010 2

We have successfully subtracted 1 from 3 by adding Minus 1 to 3 and obtaining a result of 2.